Unique Features

Unique Features World class problem solving products with Unique features

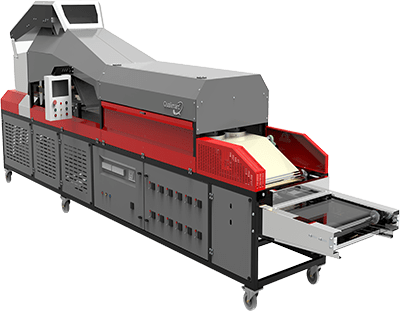

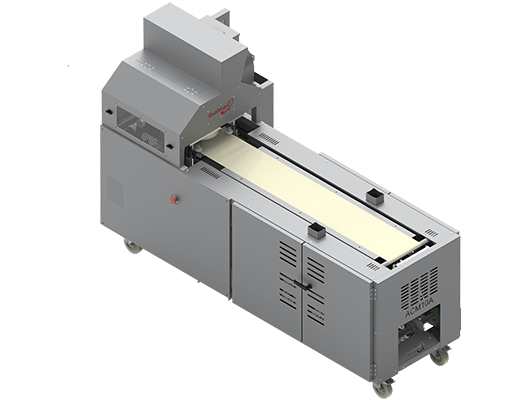

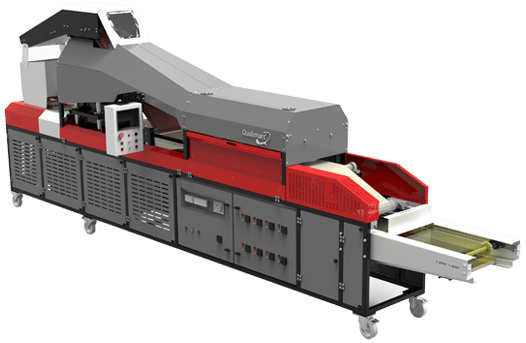

Single / Three conveyor Technology

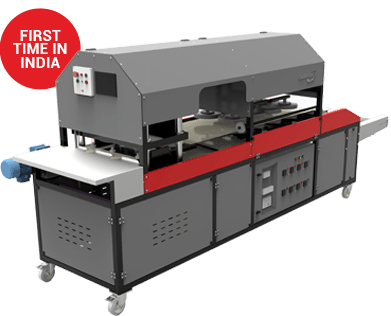

360° Chapati Baking

Unibody Concept

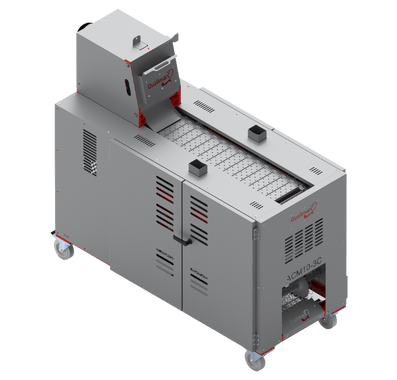

Smallest Chapati Making Machine

Travel Friendly Machine for Hotels & Caterers

Fully Automatic Machine

Single Operator Required

In Built Dough Ball Making

Automatic Cutting Wastage Collection

HMI Display For Easy Operating & Viewing

Automatic Belt Alignment System

In-built Belt Cleaning System

Hydraulic Chiller

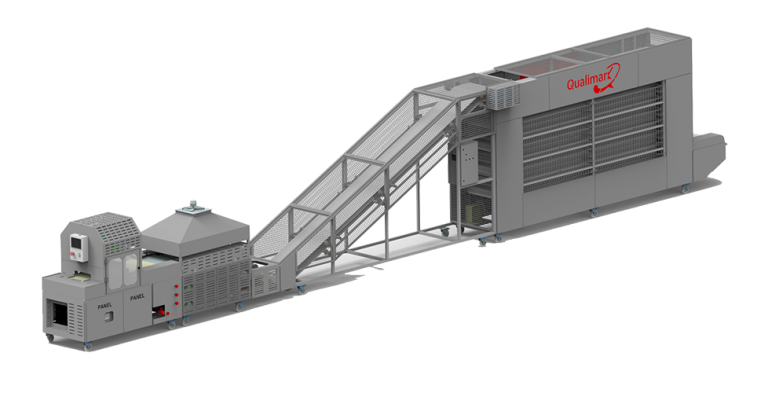

India’s Highest Capacity Machine

In-House R&D Facility

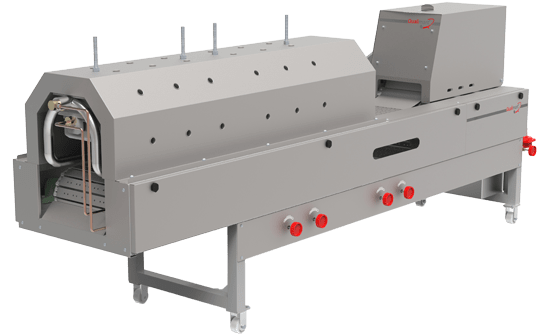

Drop Down Roasting Dish Design

Easy Khakhra Handling

In-house Designed Solid MS Hinge

Convenient Machine Speed Adjustment

In-built Oil Dropping System

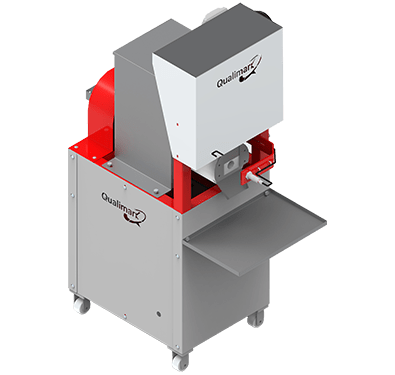

Worm Made of Food Grade Material

Easy Dough Ball Size Adjustment

Easy to integrate with other machines

Variable Output Capacity

Smooth & Precise Dough Ball Cutting

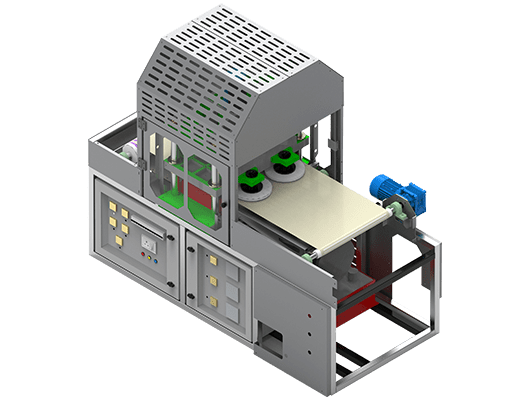

Single conveyor Technology

360° Chapati Baking

Unibody Concept

Smallest Chapati Making Machine

Travel Friendly Machine for Hotels & Caterers

Fully Automatic Machine

Single Operator Required

In Built Dough Ball Making

Automatic Cutting Wastage Collection

HMI Display For Easy Operating & Viewing

Automatic Belt Alignment System

In-built Belt Cleaning System

Hydraulic Chiller

India’s Highest Capacity Machine

In-House R&D Facility

Drop Down Roasting Dish Design

Easy Khakhra Handling

In-house Designed Solid MS Hinge

Convenient Machine Speed Adjustment

In-built Oil Dropping System

Worm Made of Food Grade Material

Easy Dough Ball Size Adjustment

Easy to integrate with other machines

Variable Output Capacity

Smooth & Precise Dough Ball Cutting