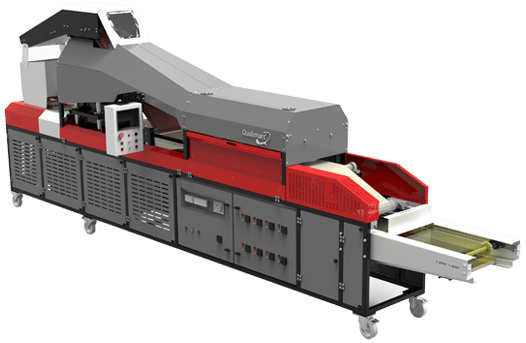

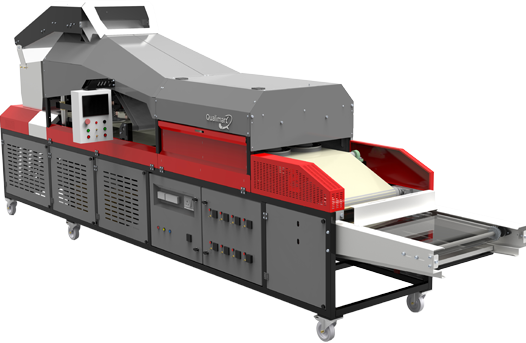

Fully Automatic Khakhra Making Machine

Precision-engineered product with Unique Features

Fully Automatic Machine

Single Operator Required

In Built Dough Ball Making

Automatic Cutting Wastage Collection

HMI Display For Easy Operating & Viewing

Automatic Belt Alignment System

In-built Belt Cleaning System

Hydraulic Chiller

Up to 50% Electricity Saving

Less Maintenance

India’s Highest Capacity Machine

In-House R&D Facility

India’s first Fully Automatic Khakhra Making Machine

India’s first Fully Automatic Khakhra Making Machine

Qualimark’s Khakhra making machine is much ahead of its time in terms of design, performance and operational capabilities. Being the first player in India to unveil a fully-automatic khakhra making machine, Qualimark has exceeded customer expectations in different aspects. An operator just has to place kneaded dough in the machine and the machine will come out with final product. Also, the machine can be operated by just one person ensuring a saving of more than 100% in terms of manpower cost while other machines require at least 2-4 persons for operations. The machine thus helps in operating with less space, increased savings due to less manpower, operating and maintenance cost.

In-house R&D Facility

In-house R&D Facility

Qualimark is one of the select food processing machinery and equipment manufacturers in the country that operates a dedicated R&D facility sprawling across 5000 sq. ft. Owing to in-house R&D facility, Qualimark has promised innovation in product design and great machines working on advanced technologies for the benefit of the end consumer, every time. Also, it has helped Qualimark to stay ahead of competition and become a leading player in Khakhra and Chapati making machines landscape. Being the core USP and differentiating factor, Qualimark’s R&D centre has helped the company to channelize its efforts in research and development of advanced machines for reputed clients around the globe.

Read More

Integrated Dough Ball Making Machine

Integrated Dough Ball Making Machine

The machine makes it easier to integrate dough ball making machine in the product line. Operations can be further automated by integrating Qualimark’s dough ball making machine with ease and in just a few seconds. This helps in getting rid of manual dough ball making process saving time, efforts and manpower cost.

Automatic Khakhra Stacking

Automatic Khakhra Stacking

Conventional machines are fitted with oil spraying systems that pour oil only on partially-roasted khakhra and do not transfer the khakhra to collecting tray automatically. Qualimark employed its R&D expertise to design an innovative oil spray system that not only sprays oil on khakhra but stacks the khakhra in collection tray. This improves operations and reduces the requirement of additional manpower for operations. Using advanced and state-of-the-art dispensing technology, the machine ensures automatic khakhra stacking.

India’s Highest Capacity Machine

India’s Highest Capacity Machine

With the help of Qualimark’s machine, a customer can achieve maximum output per shift with less operating and maintenance cost. Being India’s highest capacity machine, Qualimark’s machine promises 30% higher output and capacity when compared to other machines in the market. Despite possessing the highest capacity, machines by Qualimark are compact in size owing to Qualimark’s technologically-advanced design and manufacturing process powered by in-house R&D operations.

Advantages

- Energy-efficient machine with lesser noise as compared to other machines

- Mechanized belt adjustment guide working on an advanced design for accurate results

- Unique push pull mechanism for increasing the life of Teflon-coated belt

- Oil spraying technology for spraying oil on partially-roasted khakhra

- Dedicated operating panel for easy, convenient and streamlined operations

- In house designed heater and sensor for precision control and consistent repeatability

- Robust mechanical structure equipped with high-quality parts promising heavy-duty performance

- Powder-coated machine covers and highly-finished automotive paint-coated machine parts

- Easy-to-open body cover for convenient maintenance

Fully Automatic Khakhra Making Machine

Fully Automatic Khakhra Making Machine

Technical Specification

-

- Type

KM90A

KM90A KM180A

KM180A KM250A

KM250A

-

- Production Rate (Approx.)

- 900 Nos./Hr. Or 100 Kg/8 Hr.

- 1800 Nos./Hr. Or 200 Kg/8 Hr.

- 2500 Nos./Hr. Or 300 Kg/8 Hr.

-

- Elec. Motor (3 Phase)

- 5 HP

- 6 HP

- 7.5 HP

-

- Required Ele. Power (HP / kW) 3 Phase

- 16.75 HP / 12.48 kW

- 28.43 HP / 21.18 kW

- 41.25 HP / 30.73 kW

-

- Belt Alignment Sysytem

- Automatic

- Automatic

- Automatic

-

- Roasting Platform

- 4 Nos.

- 8 Nos.

- 12 Nos.

-

- Overall Dimensions (Ft.)

- 16.75 x 3.55 x 6.20 (L x W x H)

- 16.75 x 4.35 x 6.20 (L x W x H)

- 18.35 x 4.35 x 6.20 (L x W x H)

-

- Weight (Kg.) Approx.

- 1150

- 2000

- 2150